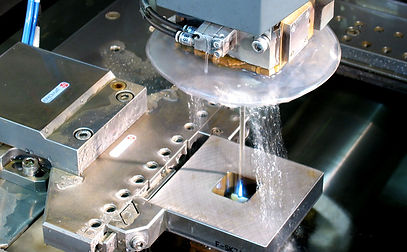

Precision Machining for Aerospace & Medical

Noormac Machining capabilities

With over 20 years of experience. Noormac Machining as become a leading provider of machined quality complex machined products. Every customer is looking for a partner to provide parts at the highest quality levels, while maintaining the best possible cost.

Our CNC (Computer Numerical Controlled) machines allow us to provide repeatability and reliability when it comes to critical dimension and high production runs, this allow us to run effectively during our production hours.

Our machining equipment includes the following processes:

-

1 " dia - Tsugami - 5-axis - Panther - Swiss Machining - 12' automatic feeder

-

1/2" dia - Hanwha - 3-axis - SL12 - Swiss Machining - 12' automatic feeder

-

12" dia - Doosan - 7-axis - Puma - Turning Center - 5' automatic feeder

-

40" x 24" x 24" - Mitsubishi - 3, 4 +1 axis - DV-1000 - Milling Center

-

15.75" x 11.8" x 8.66" - Sodick - VL400Q - Wire EDM

-

7.87" x 11.81" x 11.81" - Sodick - K1C - Hole Popper

-

40" x 20" x 24" - Manual Milling

-

36" x 8" x 8" - Manual Grinder

This equipment allows us to deliver a range of skills and services, such as:

-

5-Axis medical and aerospace machining

-

Complex Milling

-

Complex Turning

-

Exotic Alloy Machining

-

Cast and Forged Machining

-

Thin-Wall Machining

-

Gear Racks & Pinions

-

Micro-Tube Machining

Size & Tolerance capabilities:

-

Complex Milling = +/- 0.003

-

Complex Turning = +/- 0.003

-

5-axis Machining = 0.060" to 60" in degree rotation

-

Thin-wall = 0.010"

-

Highest accuracy = +/- 0.00005

-

Dimensional measurement = +/- 0.0000020

Materials and Exotic derivatives of the following:

-

Aluminum

-

Brass

-

Bronze

-

Carbide

-

Ceramic

-

Hastelloy

-

Inconel

-

Stainless Steel

-

Steels

-

Titanium

-

Tungsten